Introduction

The waste disposal project for construction and decoration in Changshu is divided into two phases: temporary treatment of mixed construction and decoration waste in Phase I, and daily treatment of such waste in Phase II. The previous article covered the Phase I project, while this article will introduce the Phase II project in Changshu. The successful operation of both phases has not only driven similar projects' development nearby but also had a nationwide impact.

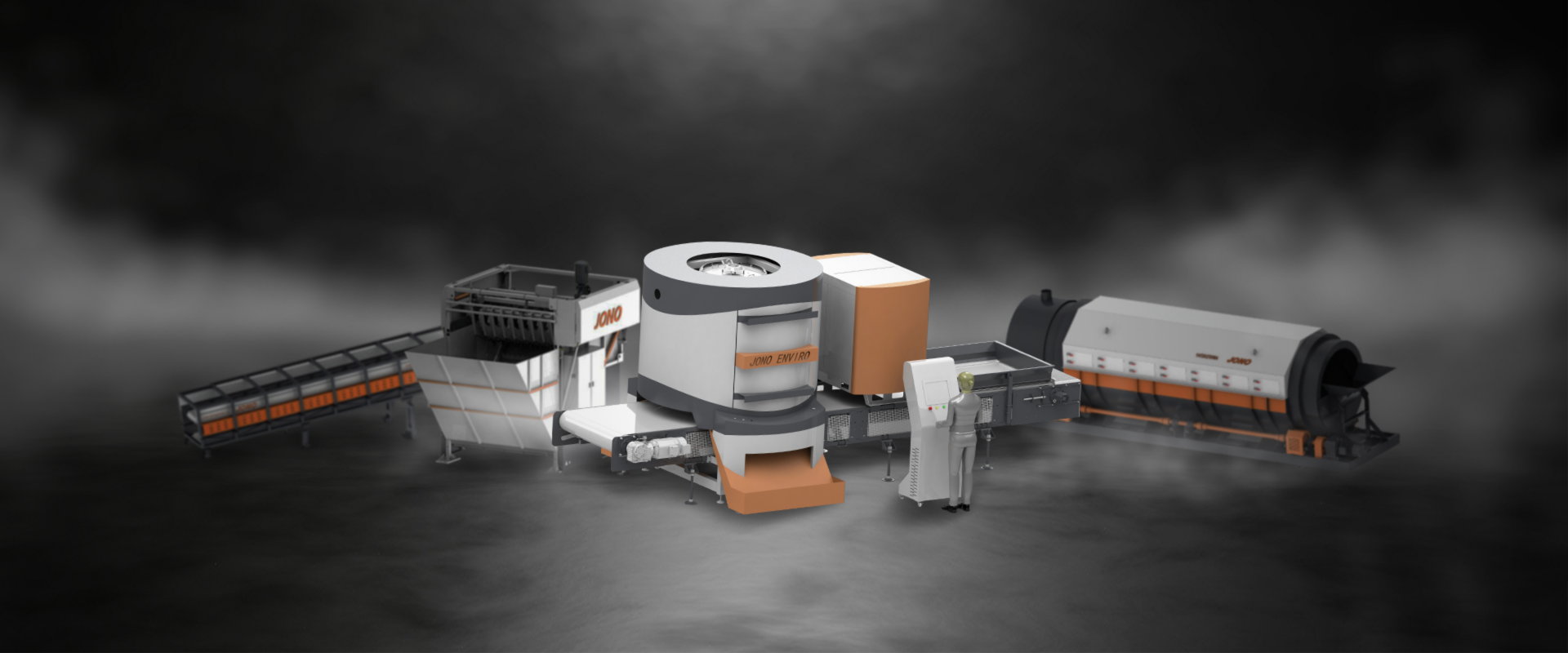

Project Overview

The second phase project in Changshu, also known as the Changshu Building Materials Recycling Center Project, is a crucial environmental infrastructure initiative covering approximately 28.75 hectares of land. It involves constructing a 55,000 cubic meter fly ash landfill and a 125,000 cubic meter landfill for non-recyclable building and decoration waste. Additionally, it includes establishing a resource recycling system with a daily capacity of 500-800 tons for building and decoration waste, ensuring an annual disposal capacity of no less than 300,000 tons.

Project Highlights

1. High Purity Aggregates

The project utilizes variable air-classifier technology to achieve gravity separation based on the density disparity between light and heavy substances in the material. Air is the preferred method of separation, with a processing capacity of up to 50T/H and impurity content in the obtained aggregate being less than 1%.

2. Anti-blocking Screening Technology

Construction and decoration waste is often dumped in an open area, where moisture causes materials to stick together and block screens. And long, strip-shaped large pieces of material can also cause the production line to stop and reduce processing efficiency. To solve the blocking problem, the project employs a highly efficient and intelligent three-dimensional anti-blocking screening technology to selectively separate long strip-shaped materials, which greatly reduces the frequency of screen mesh blockage.

3. High-efficiency Separation

This project has adopted advanced intelligent identification technology and utilized efficient separation equipment like ballistic screen to process construction waste, achieving an impressive 98% separation rate for organic and inorganic materials. Furthermore, it is equipped with a dust removal system to ensure environmentally friendly and highly resource-efficient treatment, making a significant contribution to Changshu's sustainable development.

Conclusion

The main difference between Phase I and Phase II of Changshu Construction Waste Disposal is that Phase I focuses on waste volume reduction, while Phase II emphasizes resource utilization. By combining the two, Changshu has achieved efficient waste disposal while maximizing resource utilization.