Introduction

Industrial waste is the byproduct of industrial activities, including materials rendered useless during manufacturing processes in factories, mills, and mining operations. It can be solid, semi-solid or liquid, and may be hazardous or non-hazardous. This waste has the potential to pollute soil and water bodies. Industrial waste may pollute the nearby soil or adjacent water bodies, and can contaminate groundwater, lakes, streams, rivers or coastal waters. Therefore, industrial waste cannot be left untreated.

Case Study

Today’s case study comes from Taiwan Yangbao SRF Project, one of JONO’s Industrial waste treatment solution projects.

Project Overview

The project will sort dry waste and wet waste, including coarse crushing, screening, magnetic separation and optical separation.The purpose is to select the impurities such as metals, inerts, PVC and low calorific value SRF.

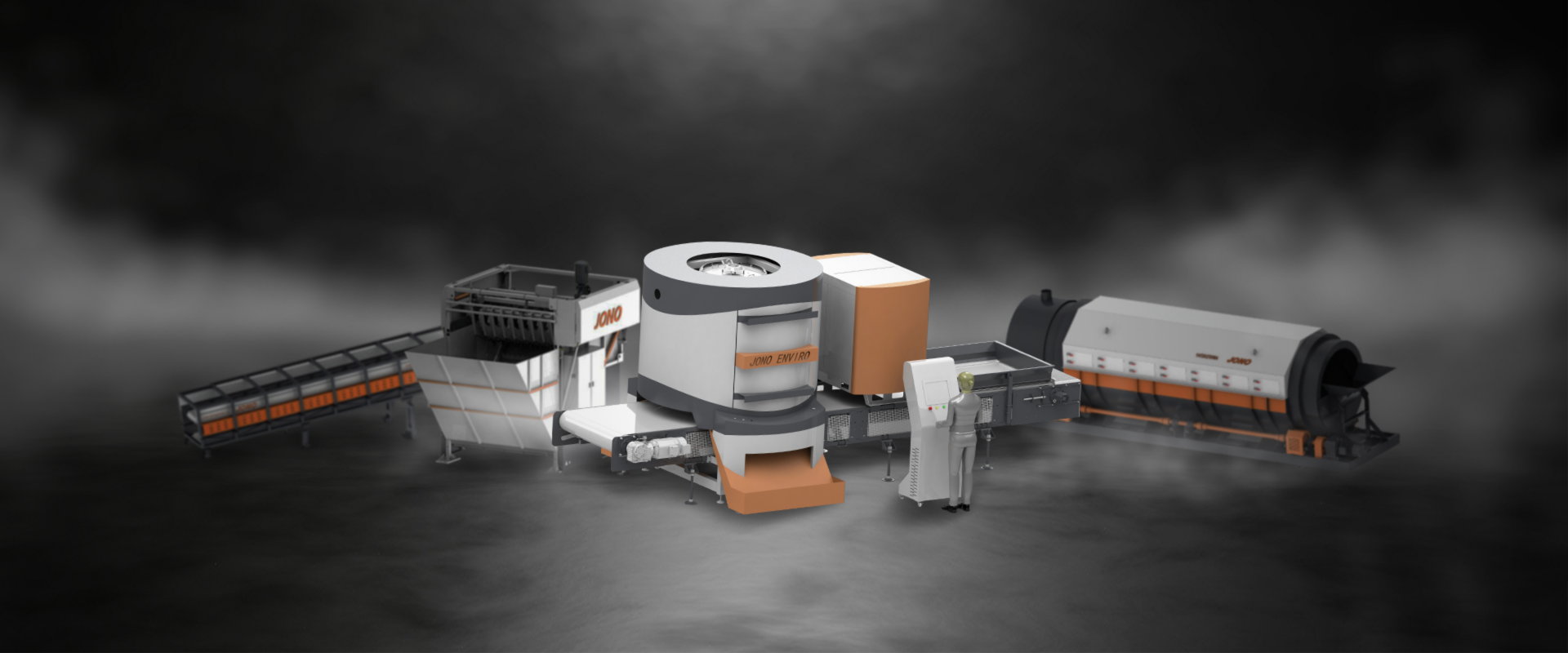

Overlooking the entire plant: Yangbao (Taiwan) SRF Project is designed to process total 300T/D of wet(mixed MSW) and dry waste(Industrial Waste)(150t/d of wet MSW waste, and 150t/d of dry industrial waste),with a daily operating time of 14 hours.

Project Process

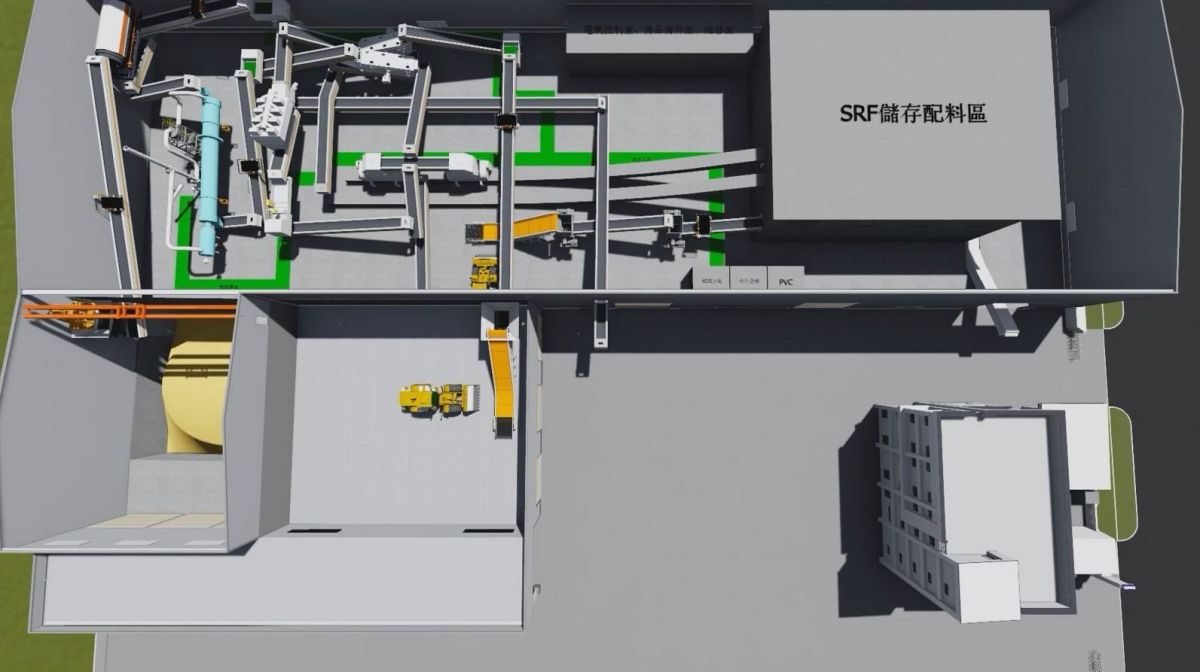

The JONO Primary shredder cuts wet waste into particles ≤250mm (Leo shredder for wet waste, Aries shredder for dry waste).

Material > 60mm

Material over 60mm is screened out by the drum screen and goes to subsequent equipment such as eddy current separator, magnetic separator.

The magnetic separator removes iron-containing substances from the material flow.

The eddy current separator sorts non-ferrous metal from the material flow.

The high-pressure density separator separates light and heavy materials, with heavy materials conveyed and discharged by belt conveyor while light materials enter the optical separator line. The optical separator removes PVC from materials, with remaining materials crushed by the shredder.

Material≤60mm

Material <60mm is screened out by drum screen and enters bio-drying system which dries it to remove moisture for subsequent processing.

Oversize material from combi waste screen will be crushed, while undersize material is transported to SRF storage area consisting of walking floor system, screw conveyors and scraper conveyors for storing, feeding and equalization.

Project Outcome

The purpose of this project is to separate and treat dry and wet waste through primary crushing, screening, magnetic separation, and optical separation, to select impurities such as metals, inerts, PVC, and low calorific value SRF. At the same time, the moisture content of the screen material with a particle size of ≤ 60mm is reduced to further increase the calorific value, and the combustible material is finely broken into fine and uniform particles. The combustible material and low calorific value SRF are respectively transported to the cache warehouse for temporary storage, and then loaded and transported to the power plant for incineration, The remaining materials are temporarily stored and transported for disposal.

https://www.youtube.com/watch?v=dC9Vt5J6pRw

If you are interested in this project, please feel free to contact us for more information.