Introduction

Mixed MSW is a general term for recyclable waste, organic waste, hazardous waste, combustible waste, etc.

Traditional waste disposal methods often have problems such as low efficiency and environmental pollution. With the economic development, the total amount of MSW shows an upward trend, there is a growing need to improve the efficiency of waste disposal. In order to realize the recycling, reduction and harmlessness of municipal solid waste, it is necessary to face the problems like garbage mixed collection, low content and calorific value of recyclable substances, high water content of garbage and etc. In view of these problems, Mechanical treatment solution is a feasible measure.

|  |

JONO’s Advanced MSW Treatment Solution

The mechanical treatment production line can greatly improve the efficiency of garbage treatment, and has an incomparable advantage in the sorting quality and processing capacity.

Jono has independently developed the MSW mechanical biological treatment (MBT) technology, and launched the automatic disposal scheme of waste classification and treatment smart factory. After the intelligent separation of mixed MSW, the disposal path for products includes: Aerobic/Anaerobic fermentation to produce high-quality biological fertilizer; plastic granulation; production of high calorific value refused derived fuel RDF.

The biological drying system reduces the water content of the material from 55% to 25% through the drying process of fully automatic control operation, and then further separates the dried material to make a high standard SRF(solid recovery fuel) which can be sold to WTE plant or cement plant.

Mechanical Treatment Production Line

The production line of Mechanical treatment program covers: crushing system, magnetic separation system, separation system, RDF preparation system, etc.

Thus the equipment includes crusher, magnetic separator, roller screen, RDF forming machine and other main equipment, all of these smart equipment can ensure the complete production line each process closely.

Case-study

Songyuan MSW Mechanical Separation Treatment Plant

Project Information

This project with the treatment capacity of 1000t/d is set for a fine sorting of MSW before they were sent to the CFB (circulating fluidized bed) for incineration. Specifically, JONO introduces the Lindner shredding technology and adopts two-stage shredding process in this project to shred the combustible materials into 80 mm fuel (SRF) so as to enhance the complete combustion rate and mitigate the pressure of treating the exhaust gas. Besides, the mechanical sorting process is also applied in this project to sort out ferromagnetic metals, in-combustibles (glass, stone, ash, etc.) and combustibles.

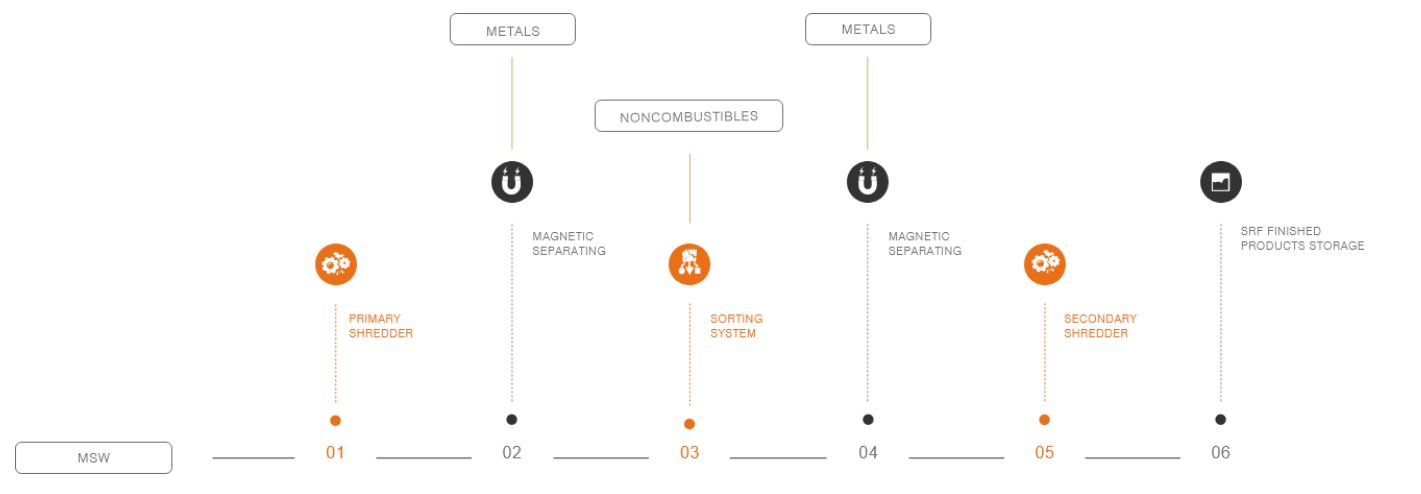

Operation Process

The sorting system screens recycled plastics, metals and other recyclables. After the intelligent separation of mixed MSW (Municipal Solid Waste), the disposal path for products includes: Aerobic/Anaerobic fermentation to produce high-quality biological fertilizer; plastic granulation; production of high calorific value refused derived fuel RDF. The operation process is just like the following picture shows:

This is just one of JONO Enviro’s MSW Treatment projects and if you want to know more about this topic, please contact us for more information.